Chimney

- Discharge flue gases to the atmosphere

- Totally sealed and protected form contamination

- Reduce the impact of greenhouse gases

- Energy Saving

- Smooth exhaust combustion gases into the air

Receivers

- Built as per Indian Foreign standards

- Capacities can be designed as per clients requirements

- Available in horizontal as well as vertical models.

Distillation Columns

Distillation is the process of separating a liquid mixture into its component parts. It is also known as fractional distillation. The distillation column is the heart of the distillation system. Industrial distillation is performed in a distillation column which is also known distillation tower. We have manufactured simple distillation columns as well as fractional distillation columns with internal packing for highly complex distillation requirements.- Packed towers are more effective when used with corrosive liquids

- Packed towers handle foaming systems better than trays

- Packings provide extra interfacial area for liquid-vapor contact, so the efficiency of the separation is increased for the same column height

- Packed columns can be shorter and more cost-efficient than trayed columns

- Random packings are easier to install than trays and structured packing

- Optimal performance of packed columns require effective liquid distributors feeding the packed bed

- Tray towers offer better predictability than packed towersTray towers are better at handling solids

- Tray towers are better at handling lower liquid rates

Storage Tanks

- Sturdy

- Sufficient stabilized

- Durable & long-lasting

- Withstands harsh weather environments

- Leak-proof

- Resistant to chemicals

- Resistant to corrosion

Industrial reboilers

Reboilers are heat exchangers typically used to provide heat to the bottom of industrial distillation columns. They boil the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation.- quieter than a furnace

- the heating system provides more consistent heat

- Boilers use less fuel to produce heat. Therefore, it is more cost-efficient

- Energy Saving

- Low maintenance

- Easy installation

The heat supplied to the column by the reboiler at the bottom of the column is removed by the condenser at the top of the column. Proper reboiler operation is vital to effective distillation. In a typical classical distillation column, all the vapor driving the separation comes from the reboiler.

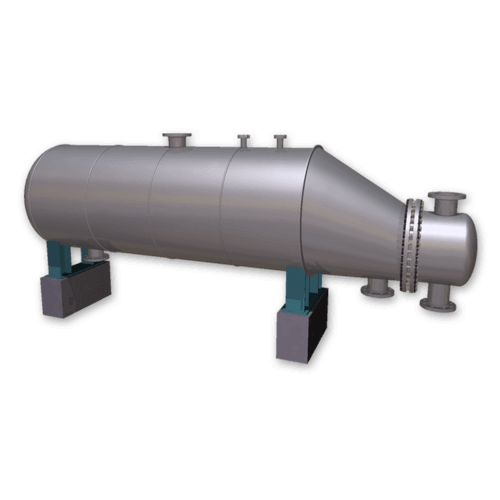

Heat Exchangers

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.- Low maintenance costs.

- High working pressure.

- High working temperatures.

- Processing of particulate or fiber products.

- High security in aseptic processes.

- Easy inspection and disassembly.

- Easy to enlarge.

Reaction Vessel

Reaction Vessel is one of the most important equipment of any chemical, food, drugs, dyes, and allied industries.- Magnetically coupled agitated vessels for vaccines

- Blending/mixing vessels for liquid oral, IV fluid, injectables and other liquid applications

- Storage tanks for water for injection and purified water storage systems

- Pressure vessel for various applications

- GMP reactors for crystallization, blending, heat transfer application with scrapper with agitator, anchor agitator, custom built agitation solutions

- Sterilizers for intravenous system

- The storage capacity of this vessel is maximum: 5 KL

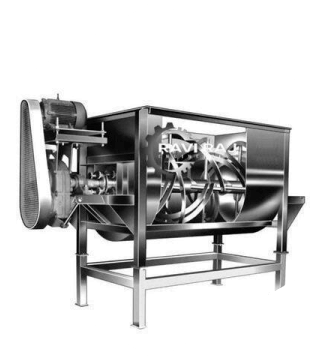

Ribbon Blender

Ribbon blender are used for all dry foods products, nutraceuticals, protein powder mixes, dry juice mixes, chemicals, fertilizer, insecticides, colorants, resins and polymers. The moderate shear of the ribbon or paddle naturally breaks down lumps and agglomerates.- Blending large volumes of dry solids.

- Dry powder to wet phase mixing.

- Mixing of bulk drugs, chemicals, and cosmetic powders.

- Dry Blending of capsule formulations.

- Lubrication of dry granules in large quantity.

- Heating, cooling, and drying of materials./li>

- Coating solid particles with small amounts of liquids to produce formulations.

Ribbon Blender that we offer is globally appreciated for its superior technology & acceptable price range. It is widely used for mixing dry powder, which is usually a free flowing solid substance. Our Ribbon Blender fabricated in well equipped infrastructure is definitely worth buying & a very profitable industrial investment. These are proven agitator construction based blenders that help in providing triple mixing action, which ensures efficient blending. These blenders are precisely designed to impart the complete linear and radial motion for effectively mixing the homogenous material. We offer them in different configurations and can be customized as per the preferences. With an experience of over two decades in handling the various process applications in Dyes, Intermediates, Pigments, Pesticides, Fine Chemicals, Rubber Chemicals, Bulk Drugs, API and Nutraceuticals.

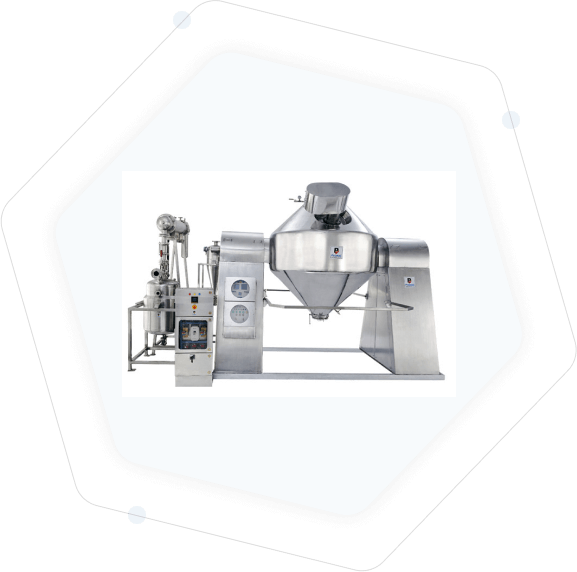

Rotocon Vacuum dryer

Rotocon vacuum dryers are multipurpose drying units & are extremely useful for uniform and low temperature drying of heat sensitive chemicals, pharmaceutical formulations, fine chemicals etc.- GMP models for final pharma products

- Totally sealed and protected form contamination

- Quick loading & unloading

- Fast drying

- Energy Saving

- M.O.C Mild steel grades and stainless steel grades

- Choppers can be provided

Agitated Nutsche Filter

Agitated Nutsche filter (ANF) is a filtration technique used in applications such as dye, paint, pharmaceutical production, and wastewater treatment. Safety requirements and environmental concerns due to solvent evaporation led to the development of this type of filter wherein filtration under vacuum or pressure can be carried out in closed vessels and solids can be discharged straightaway into a dryer.- Vacuum or pressure filtration possible.

- Inert gas atmosphere can be maintained.

- Minimal contamination of the cake.

- Very high solvent recovery.

- Considerable saving in manpower.

- Solvents are in closed systems, so no toxic vapors are let off in the atmosphere.

- Personal safety is maintained and heat transfer surfaces can be provided to maintain filtration temperature.

Octagonal Blender

RAVI RAJ ENGINEERING makes an Octagonal Blender which is an efficient and versatile blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. The Octagonal Blender gives the best result for granules due to the very slow speed and octagon shape of the container. It can be used for making Pharmaceutical, Food, Chemical and Cosmetic products, etc.- Easy for loading and unloading of material

- Suitable for dry mixing of products in granular form.

- All parts are made out of SS304/SS3116 or L quality material, as per customer requirements

- Easy for cleaning.

- The octagonal shape b slow speed of rotation gives sufficient continuous movements to the granules, resulting in good quality.